The challenge

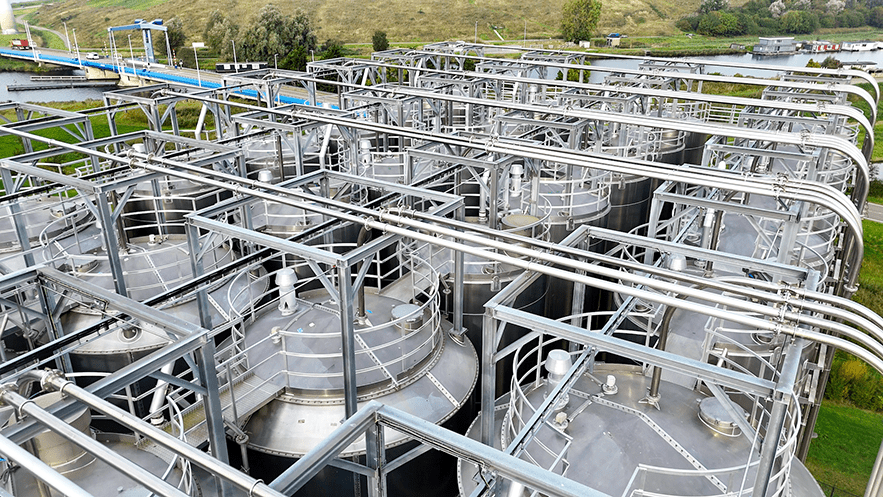

Silobedrijf De Vrede specialises in blending powders into customer-specific end products, primarily for the petrochemical industry. The key challenge was to set up a new production process that:

- complied with stricter nitrogen regulations,

- guaranteed high and consistent product quality,

- and could be controlled efficiently and in a future-proof manner.

In addition, there was a clear need for greater insight into the entire process, from raw material intake to dispatch, with a strong focus on process control and error reduction.terke focus op procescontrole en foutreductie.

The approach

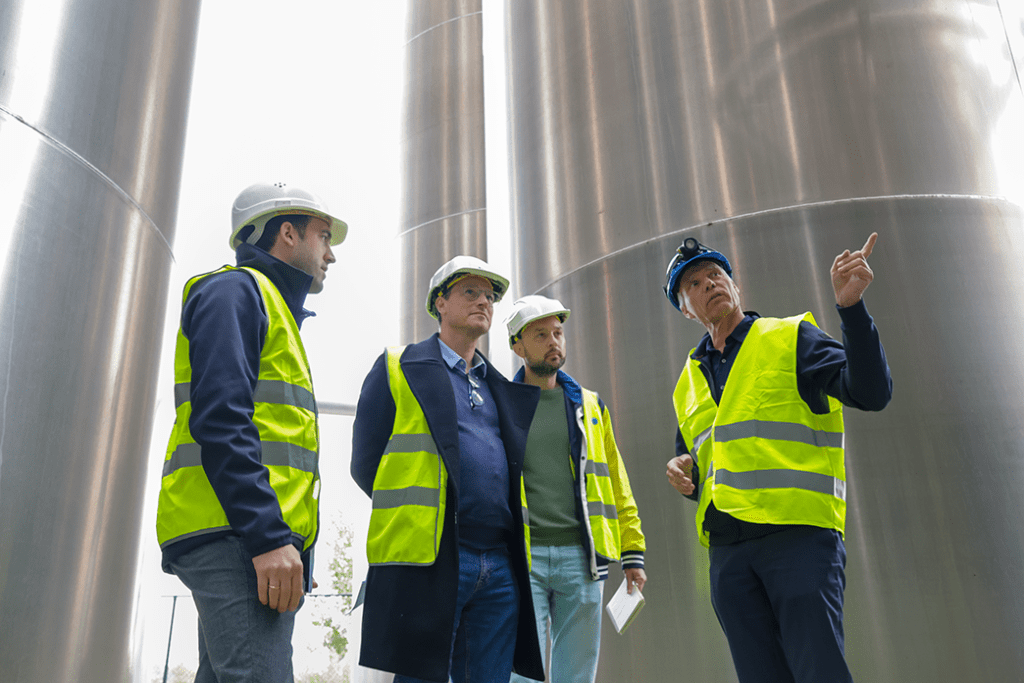

Within this project, VMA – as Zeppelin’s PMT partner – took responsibility for the full scope of electrical engineering, automation, visualisation and industrial digitalisation. Thanks to this integrated approach, the customer was fully unburdened throughout the project.

Specifically, VMA delivered:

- Process control and automation via PLC systems, including cabling and machine control.

- SCADA visualisation, providing operators and office staff with real-time insight into the process.

- Industrial digitalisation through an integrated MES and WMS solution that actively guides operators in their daily tasks.

- ERP integration, seamlessly linking inventory management and order management to production.

Through close collaboration between VMA’s E&I team and industrial digitalisation team, a coherent and scalable total solution was realised quickly. Existing processes at Silobedrijf De Vrede were first thoroughly analysed, ensuring that the digital solutions fully aligned with the reality on the shop floor.

The result

Thanks to VMA’s solution, Silobedrijf De Vrede now benefits from significantly improved control over its production process:

- Higher and more stable product quality through accurate process control.

- Fewer errors on the shop floor thanks to operator guidance and full digitalisation of the production flow.

- Real-time insight into production, inventory and processes.

- A future-proof setup, built on a scalable digital foundation that enables further optimisation.

The impact is tangible at every level, from operators to management. Process knowledge is safeguarded, employees can be trained more quickly, and the organisation can respond faster to changes in demand or regulation.

Unburdened through collaboration

A key success factor in this project was the close cooperation between VMA and Zeppelin. For Silobedrijf De Vrede, this resulted in a fully transparent approach: one integrated solution, without complexity for the end customer. This level of unburdening was explicitly experienced by the customer as a major added value.

Even after implementation, VMA remains involved through ongoing support and 24/7 assistance, ensuring continuous operation and further optimisation of the production process.

One partner, from cable to software

With this project, VMA once again demonstrates the strength of its PMT approach: a total solution ranging from medium-voltage installations to ERP integration, fully tailored to the customer’s specific needs. Today, Silobedrijf De Vrede operates a modern, digital production environment that is ready for the future.