The project

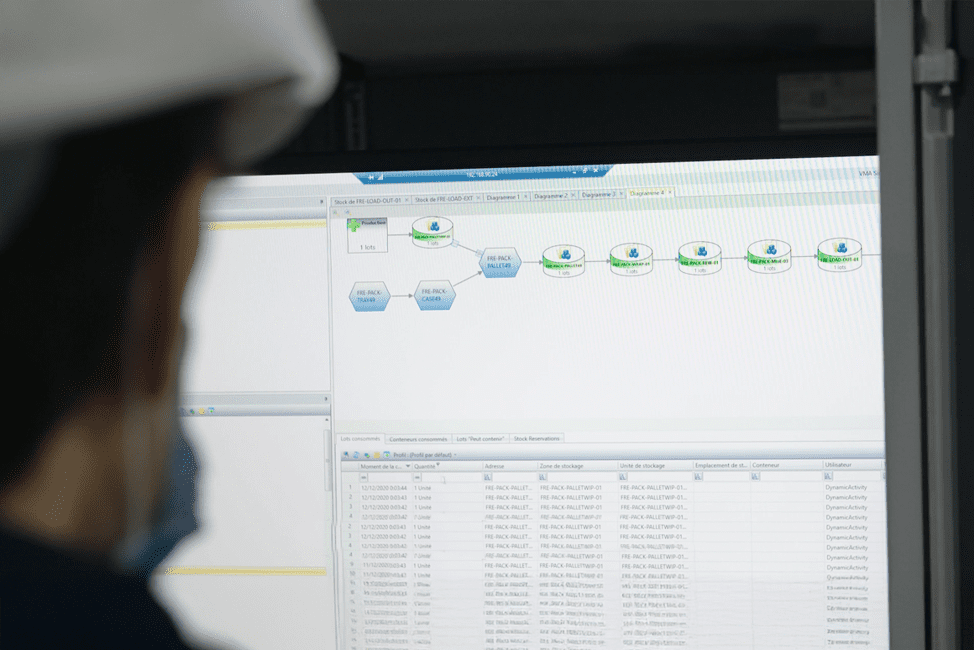

The MES project at Mydibel involved a complete digitalization of the factory—from the reception of raw materials to production and shipping. Some of the key components of the project include:

- Digitalization of production flows

- Planning, execution, quality control, and warehouse management are integrated into a single system.

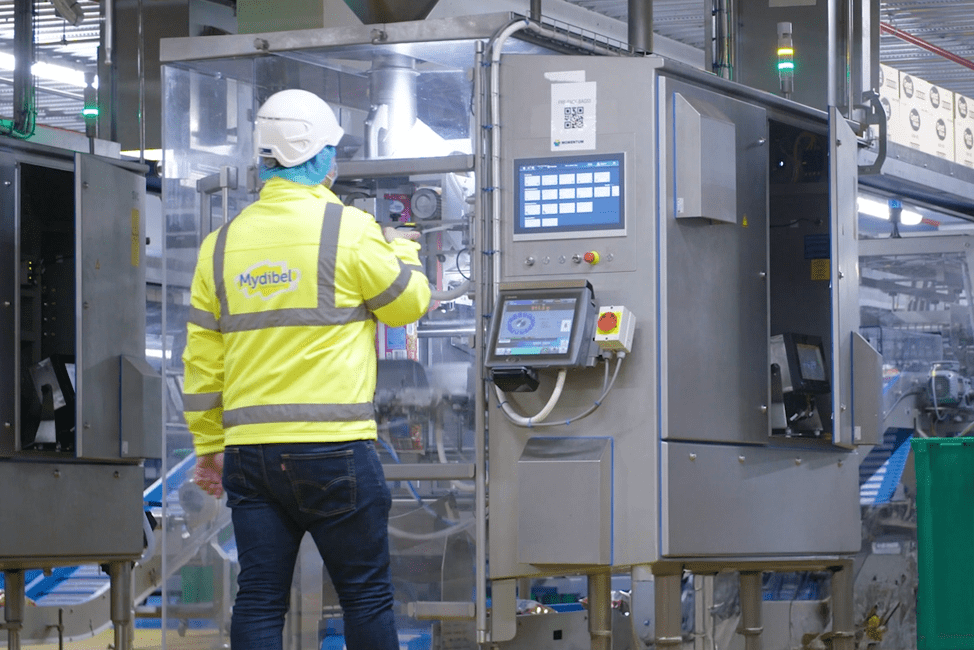

- Interaction between operators and machines is fully optimized.

- Traceability and quality

- Essential in a food production environment, the MES ensures full product traceability.

- Real-time monitoring of quality parameters.

- Flexibility

- Tailored to the specific needs of each Mydibel factory.

- The flexible MES structure allows for easy adjustments.

- Data analysis

- Large volumes of data are captured for analysis and process optimization.

- Errors are reduced thanks to automated workflows.

An innovative approach

The MES system at Mydibel not only delivers short-term benefits such as improved efficiency and fewer errors, but also lays the foundation for a long-term vision.

The ultimate goal is to develop an autonomous factory within the next 10 years. This factory will be highly digitized, with people taking on more strategic roles rather than being involved in daily operational tasks.

Benefits of MES

- Data insights

Process improvements based on in-depth data analysis. - Efficiency

Optimized production processes and reduced downtime. - Traceability

Vital information readily available for audits and quality control. - Flexibility

A system that adapts to the unique requirements of each plant.

The result

With the implementation of MES, Mydibel has taken a major step toward the factory of the future. The combination of cutting-edge technology and a strong focus on quality and traceability positions the company for a sustainable and efficient future.

VMA is proud to have contributed to this ambitious project and remains a trusted partner for the digitalization of production environments.