The project

Constructed between 2020 and 2021, the Innocent factory is a greenfield project for which VMA managed the entire E&I scope (Electrical & Instrumentation). This included:

Engineering

- Design of electrical and pneumatic systems

- TIG welding of stainless steel structures and cable trays

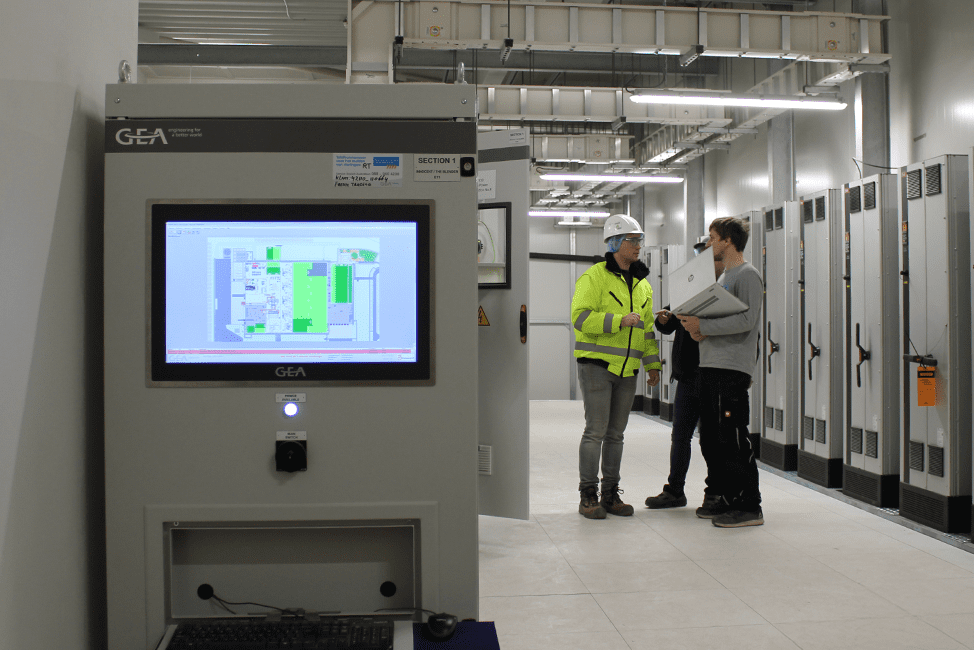

- Design and construction of MCCs (>70 meters, 12,000A) and control panels

Installation

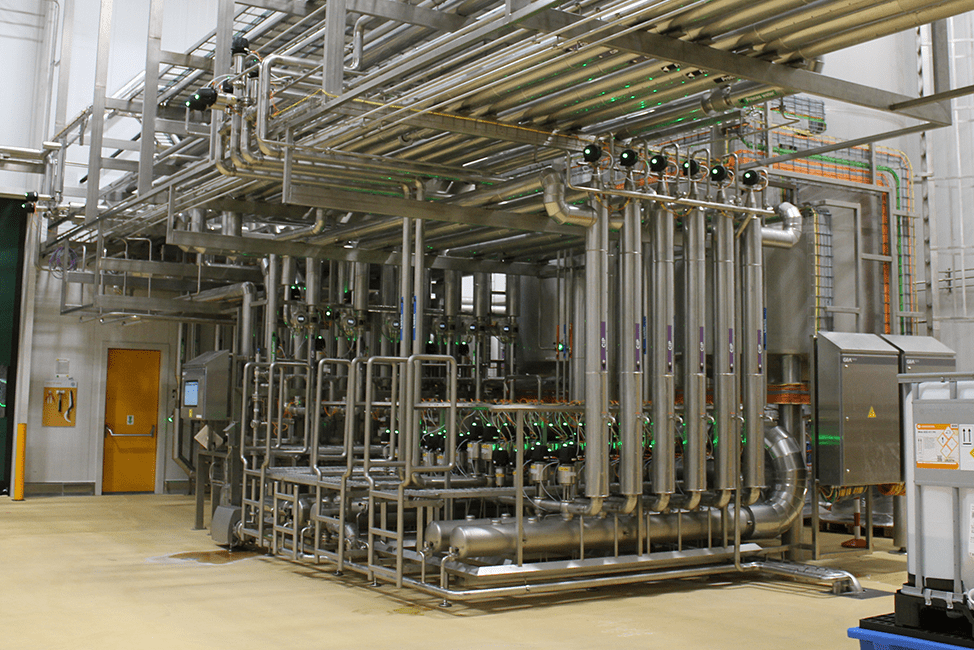

- Cabling and connection of over 200 motors and frequency converters

- More than 150 km of cable and 1,500 valves installed

- Deployment of a complex network, including fiber optics and various bus systems such as AS-i, PROFINET and Ethernet

Testing and commissioning

- IO testing and extensive system checks

- Commissioning of equipment and instrumentation

Technical innovations

The factory uses an integrated AS-i bus system for efficient communication and control across all systems. Combined with advanced technologies like PROFINET and fiber optic networking, this ensures maximum reliability and scalability. VMA’s end-to-end control over the project—from engineering to commissioning—enabled the team to meet tight deadlines while delivering top-tier quality.

Collaboration and expertise

Thanks to close collaboration with GEA and the broad range of expertise within VMA, the project was completed in record time. The challenges of short lead times and strict quality requirements were successfully met through coordinated efforts by VMA’s teams.

The result

The Innocent “the Blender” factory is now one of the most sustainable production facilities in Europe. This project demonstrates how innovative electrotechnical solutions and an integrated approach can contribute to both environmentally friendly and highly efficient production processes. VMA is proud to have contributed to this groundbreaking achievement.