A reliable partner for ENOUGH

Jens Andriessen, Design & Build at ENOUGH, is responsible for constructing the company’s new factory. In his search for a reliable infrastructure partner, he quickly found his way to VMA. From the very first contact, he had a strong sense of confidence, explaining that VMA had already demonstrated its expertise in electrical installations and automation processes—exactly what the project required. He adds that their passion and enthusiasm made it clear that a strong team was standing by their side.

“We knew from the beginning that the project had to move quickly. Fortunately, VMA responded flexibly and smoothly to unforeseen circumstances. Thanks to their proactive approach, we saved a lot of time and met the deadlines.”

Jens Andriessen, Design & Build at ENOUGH

Like with any ambitious project, challenges were inevitable. The team knew from the start that the project would need to move quickly. Fortunately, VMA responded flexibly and efficiently to unforeseen circumstances. Their proactive approach helped save valuable time and ensured that all deadlines were met.

Thanks, MOM

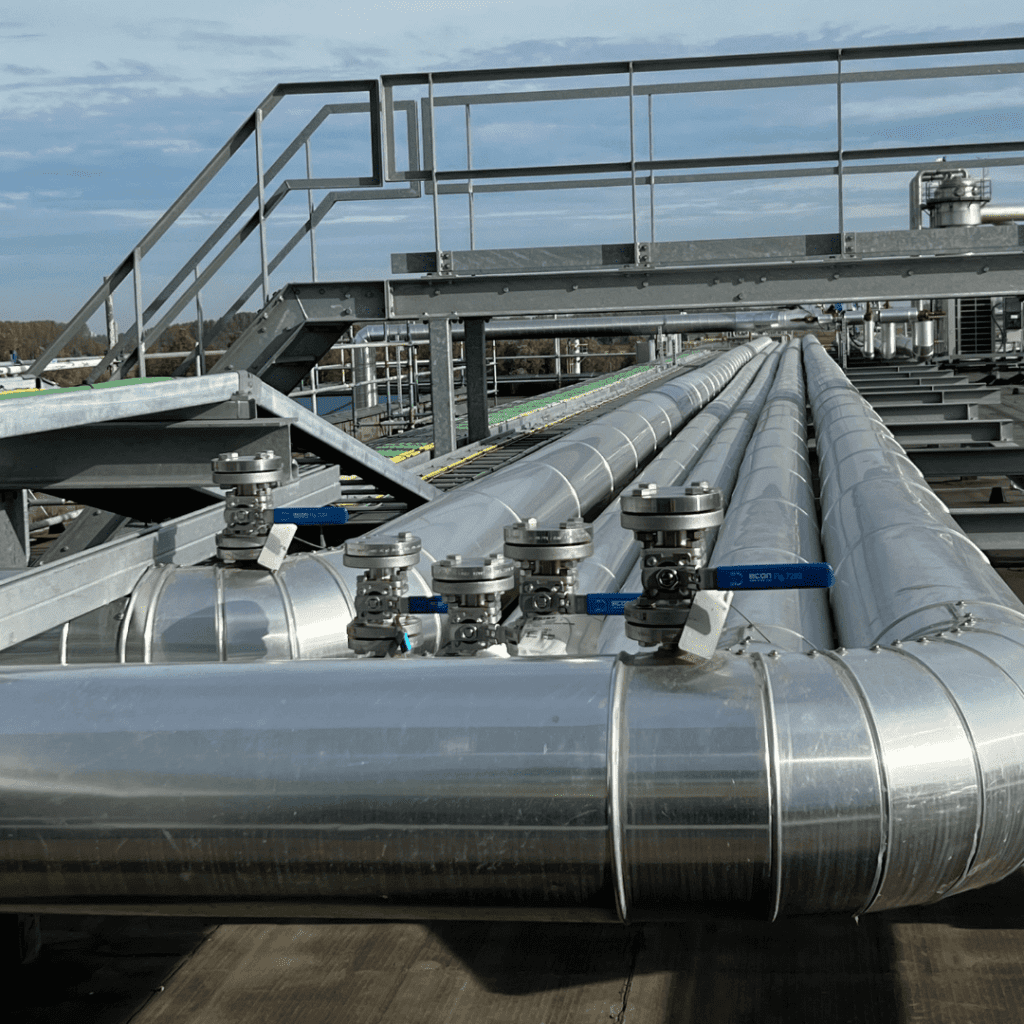

Geert De Duytschaever, Business Development Manager at VMA, receives all incoming project requests in his role as commercial point of contact. He says he remains impressed by what has been achieved. For this project, VMA executed all Processing & Manufacturing Technologies (PMT) work—from designing and building the electrical switchboards and control panels to managing the complete field cabling. All of this was developed in-house, which he considers one of VMA’s key strengths.

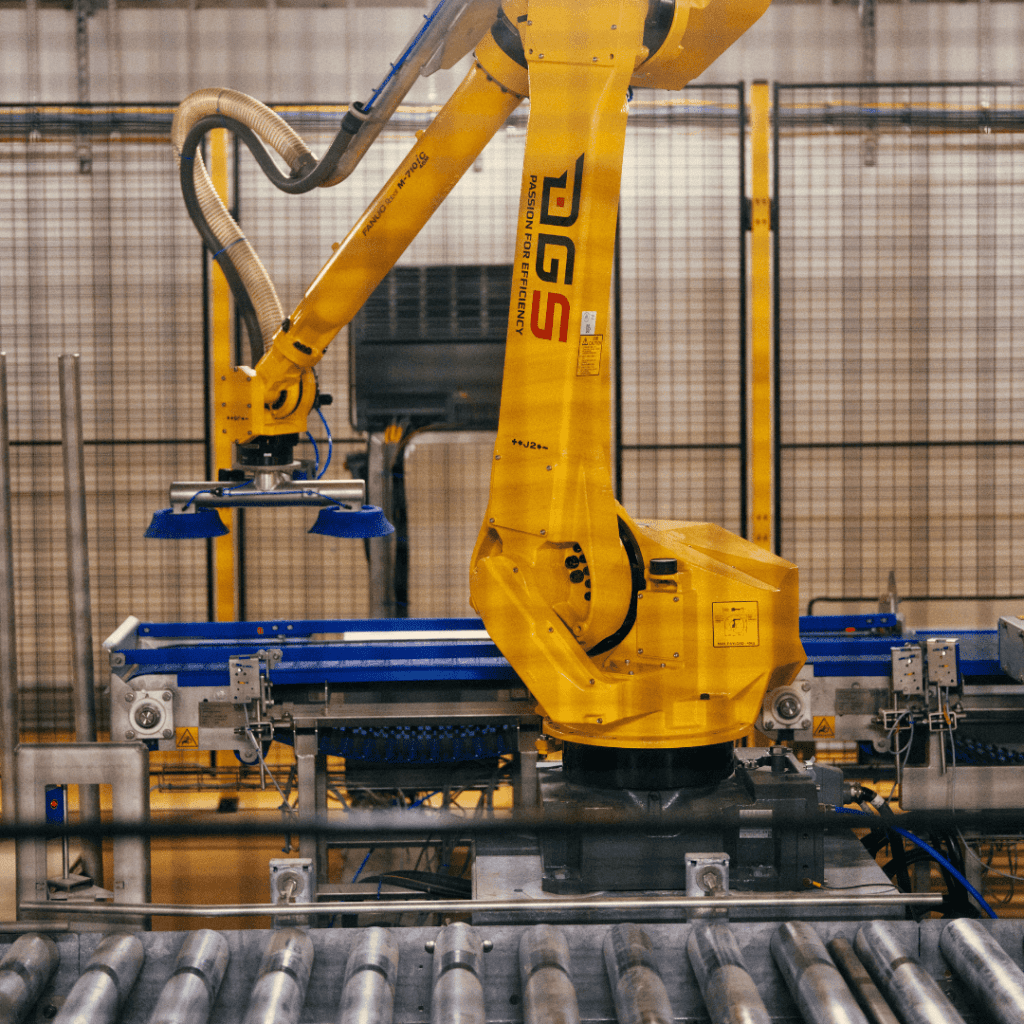

Once a factory is fully operational, VMA often remains involved through what it calls MOM: Manufacturing Operations Management. This software collects data that can be used to continuously optimize the production process. Geert highlights how critical automation is to this pilot project, especially since production must begin as soon as an order is received. That’s why MOM was also implemented at ENOUGH—to ensure everything runs as smoothly as possible.

Toward an autonomous factory

The MOM software is developed by VMA itself, thanks to colleagues like Software Engineer Roel Stevens. For this project, they used Siemens PCS7, a program specifically designed for automating industrial processes. Roel notes that their goal for ENOUGH was to create a nearly autonomous factory. But not everything happens behind a screen. Due to tight deadlines, multiple tests had to be conducted in quick succession. Each day, results were reviewed with all stakeholders, allowing the team to make adjustments where necessary. Roel reflects that it was a complex assignment, but the close collaboration led to a very strong result.

A total solution

As Project Manager for Processing & Manufacturing Technologies, Floris De Meerleer closely monitored every aspect of the ENOUGH project. He emphasizes that this was a true end-to-end project, covering everything from engineering and electrical panel construction to software development. Based on this successful delivery, the client entrusted VMA with additional responsibilities, including access and data control, as well as MOM integration. Floris explains that when VMA brings its full range of skills and expertise to the table, it takes the technical burden off the client—allowing them to fully focus on their product. Being able to apply their PMT technologies on such a large scale, he concludes, is truly remarkable.