High-performance electrical solutions for Daikin’s test center

In 2022, Daikin began construction of a state-of-the-art test center at the Science Park of Ghent University. Takenaka Europe is managing the project and brought in VMA’s Building Technologies Electro department to handle the electrical systems for the office areas.

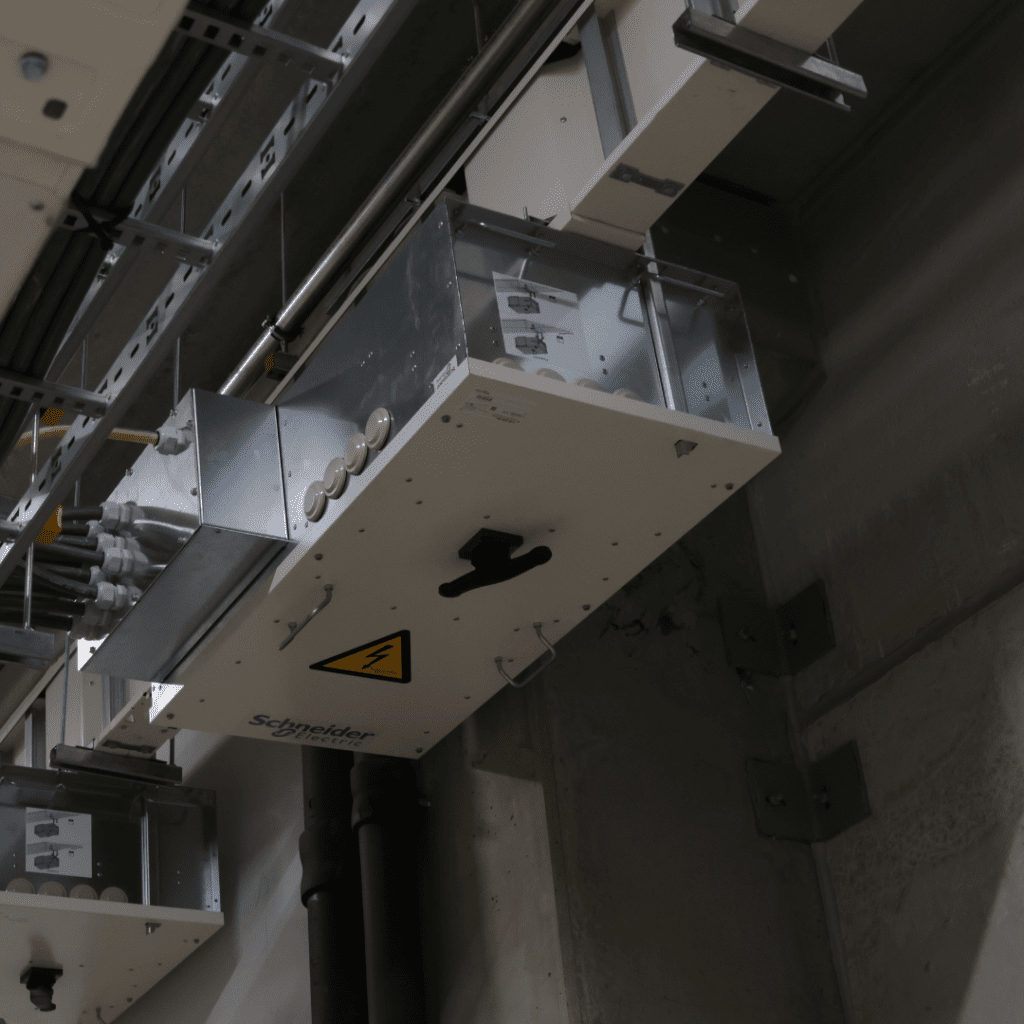

“The scope includes both high- and low-voltage installations as well as power distribution,” explains Nicolas Nicolaus, Commercial Director at VMA. “We’re also installing several low-voltage systems, including fire detection, intrusion prevention, public address systems, CCTV, and the data network.”

The numbers for the high-voltage installations highlight the project’s scale. “We are installing five high-voltage transformers with a combined capacity of 6,630 kVA,” Nicolas continues. “For the low-voltage systems, around 30 distribution boards will be installed. Meanwhile, Daikin has entrusted our Electro team with the complete power distribution for the research center.”

A challenging environment

VMANAGER and PMT have recently joined the project to take on the complex test room infrastructure. In total, the facility will house 40 test chambers, of which VMA is responsible for 20 in the first phase.“We’re delivering full automation for the heating and cooling production in the test rooms,” says Pascal Kinoo, Commercial Manager at VMA.

“The manufacturer needs to test products like air conditioners and heat pumps at a wide range of temperatures—ranging from -38°C to +85°C.”

Pascal explains how the process works:

“We deliver five different heating and cooling media to the end users at the right temperatures and flow rates, all controlled through complex regulation loops. PMT’s experience in functional documentation and software design convinced Daikin to partner with us.

In addition, VMANAGER allows for real-time process visualization and control. Our software has proven itself in numerous environments, and this project allows us to expand its capabilities even further.”

Continuous improvement

Daikin’s new test center is designed to be a climate-neutral facility—a place where innovation and sustainability meet. This aligns perfectly with VMA’s mission but also presents numerous challenges.

“For example, we must ensure that residual heating and cooling are not wasted but transferred to other test rooms,”

explains Pascal.

“We also consider practical needs: employees can reserve a test chamber via a scheduling system. This allows us to forecast future heating and cooling demands. Any shortfalls are flagged in advance.”

But what happens if one test requires cooling while another needs heating at the same time?

“That’s where it becomes a real challenge to guarantee the correct temperature in each chamber,” Pascal notes.

“Together with Daikin, we are working continuously to improve system stability. We rely on all available process parameters—storing ‘big data’ to identify correlations and optimize our control models accordingly.”